Identify Key Contamination Risks in Liquid Filling Machines

Common Sources of Contamination in Cosmetic Filling Lines

Microbial growth from stagnant product residue, worn seals releasing particulates, and insufficient sterilization between batches are primary contamination sources. High-moisture environments near liquid filling machines accelerate biofilm formation, while incomplete clean-in-place (CIP) cycles leave 18% more contaminants in nozzles, according to 2023 sanitization audits.

How Residue and Cross-Contamination Compromise Product Safety

Residual formula in valves and transfer lines causes cross-contact between incompatible ingredients, often leading to preservative breakdown. Particles under 50µm can bypass standard filters and trigger allergic reactions in 1 out of every 200 users, as reported by Dermatology Times (2022).

Mapping High-Risk Points in the Liquid Filling Process

Critical contamination zones include:

- Product-contact surfaces: Nozzles, hoppers, and tubing junctions

- Environmental exposure areas: Open filling chambers and conveyor entry points

- Post-process components: Capping stations and label applicators

Rising Trends in Product Recalls Due to Microbial Contamination

A 2022 FDA report found that 34% of cosmetic recalls were due to microbial contamination—a 12% increase since 2019. Water-based serums and natural formulations had 2.3 times higher contamination rates, largely due to reduced synthetic preservatives (Journal of Cosmetic Science 2023).

Implement Effective Cleaning and Sanitization Protocols for Liquid Filling Machines

Contamination control requires three proven strategies: standardized cleaning schedules, manual disassembly of critical parts, and automated clean-in-place (CIP) systems. A 2023 hygiene audit traced 90% of microbial contamination to poorly cleaned nozzle assemblies and valve dead zones.

Standardized Scheduled Cleaning Procedures for Filling Equipment

Adopt a tiered cleaning schedule:

- Daily: Flush all product-contact surfaces with water above 70°C and FDA-approved disinfectants

- Weekly: Deep-clean filler heads and gaskets using validated biofilm removers

- Monthly: Inspect stainless steel surfaces for pitting or corrosion under 10x magnification

Manual Cleaning of Critical Filling Machine Components

Operators should disassemble valves and nozzles daily—especially on tool-free designs—since 78% of contamination hides in crevices undetectable during routine checks. Clean O-rings and rotary joints with non-abrasive brushes and replace worn seals every 300 operating hours.

Using Clean-in-Place (CIP) Systems for Automated Sanitization

CIP systems reduce human error by 63% (PMMI 2022), circulating a 4D cycle (detergent, acid, rinse, sanitizer) at 2.5 m/s flow velocity. Equip CIP programs with turbidity sensors to ensure final rinse water meets USP <1231> purity standards.

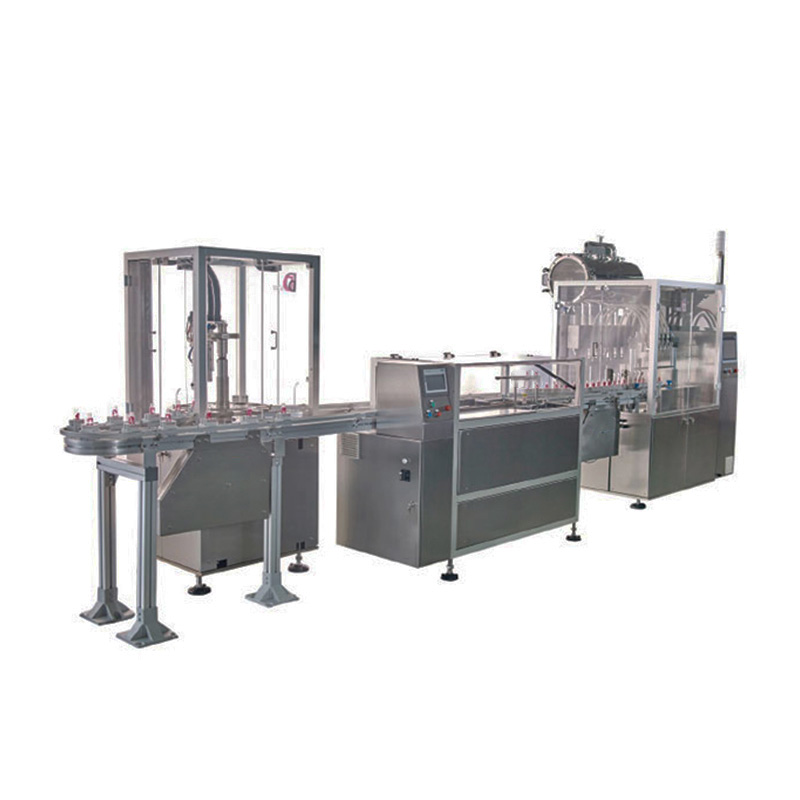

Select Sanitary Equipment Design to Minimize Contamination Risk

Key Features of Sanitary Liquid Filling Machine Design

Modern machines designed for contamination prevention use smooth, non-porous materials like 316L stainless steel, which resist microbial adhesion and chemical degradation. Industry data shows surface roughness below 0.5 mm reduces microbial risk by 68% compared to textured surfaces. Essential design features include:

- Radius corners (∅3mm) to prevent residue buildup

- Full CIP compatibility for automated sanitation

- Sealed joints that block lubricant migration into product zones

Choosing Equipment for Easy Disassembly and Cleanability

Machines requiring over 60 minutes for disassembly increase contamination risks by 42% due to incomplete cleaning (FDA 2022). Prioritize models with:

- Tool-free access to nozzles, valves, and seals

- Color-coded components to avoid misassembly

- Fewer than 25 parts in direct product contact zones

Case Study: Reducing Downtime with Stainless Steel, CIP-Compatible Filling Machines

After replacing polymer-based systems with CIP-ready stainless steel fillers, a cosmetic manufacturer cut unplanned downtime by 30%. The upgrade eliminated manual scrubbing and achieved 99.98% biofilm removal in post-cleaning swab tests, based on hygiene performance data.

Ensure Compliance with GMP, FDA, and Industry Sanitation Standards

Core GMP and FDA Requirements for Cosmetic Liquid Filling

Manufacturers need to stick to Current Good Manufacturing Practices (CGMP) as outlined in FDA regulations 21 CFR 700 through 710. These rules basically require clean facility designs, proper cleaning protocols that have been tested and proven effective, plus staff who know what they're doing to stop any kind of contamination from microbes or chemicals getting into products. The equipment itself has got to hold up against constant cleaning cycles without rusting out or leaving behind stubborn residues, something the FDA specifically addresses in their guidelines. Looking at actual data from last year, about one out of every eight FDA enforced product recalls was because companies weren't following these sanitation standards properly on their filling lines, which speaks volumes about how critical this aspect really is for maintaining quality control.

Meeting Regulatory Standards for Equipment Sanitation (FDA, OSHA)

The FDA sets residue limits at ≤1 µg/cm² on nozzles, valves, and product-contact surfaces. OSHA ensures worker safety during manual cleaning tasks. Automated CIP systems support compliance with both agencies. Facilities must conduct quarterly swab testing and monitor airflow to maintain particulate levels below 100,000 particles/m³ in filling zones.

Preparing for Audits: Documenting Cleaning and Maintenance Logs

Audit-ready facilities maintain digital records of cleaning schedules, part replacements, and operator certifications. Automated traceability reduces documentation errors by 63% versus paper logs (2024 Quality Assurance Report). Key documents include CIP validation results, sanitizer concentration logs, and preventive maintenance timelines for pumps and seals.

Control Environmental Factors in Filling Areas

Maintaining Water Quality for Rinse and CIP Cycles

Poor water quality compromises rinse effectiveness and promotes microbial growth. A 2023 study in the Journal of Pharmaceutical Innovation showed that rinse water exceeding 0.5 CFU/mL increases contamination risk by 240%. Best practices include:

- Use reverse osmosis (RO) or UV-treated water meeting ASTM Type 1 standards

- Test weekly for endotoxins, pH, and conductivity

- Filter water entering CIP systems to ≤ 5 µm

For effective biofilm removal, maintain water temperatures above 70°C (158°F) during CIP cycles, avoiding thermal damage to sensitive ingredients.

| Water Treatment Method | Microbial Reduction | Maintenance Frequency |

|---|---|---|

| Reverse Osmosis | 99.9% | Quarterly membrane replacement |

| UV Disinfection | 99.6% | Annual bulb replacement |

| Microfiltration | 95% | Weekly integrity tests |

Managing Air Quality to Reduce Particulate Contamination

Airborne particles larger than 0.5 microns threaten product sterility. Data shows HEPA-13 filters reduce ambient particulates by 82% in cosmetic production areas. To maintain air quality:

- Achieve ISO Class 7 cleanliness (< 352,000 particles/m³ for ≤0.5 µm)

- Install laminar airflow hoods at machine inlets

- Maintain humidity between 35–50% RH to minimize condensation

One multinational pharmaceutical company reduced recall incidents by 80% in 2022 after deploying real-time air quality monitoring with particle counters and differential pressure alarms.

Table of Contents

- Identify Key Contamination Risks in Liquid Filling Machines

- Implement Effective Cleaning and Sanitization Protocols for Liquid Filling Machines

- Select Sanitary Equipment Design to Minimize Contamination Risk

- Ensure Compliance with GMP, FDA, and Industry Sanitation Standards

- Control Environmental Factors in Filling Areas